The first electric pump I installed was an external pump. Great pump. Worked very well for many years. However, there were some things about an external pump which are not ideal.

One problem I had was the sound. I was always able to hear the constant buzz. When first installed, it was not too bad, but a passenger often asked “what is that noise?”. As time passed, I think the buzz got louder. Despite a pretty loud exhaust, you could still hear the fuel pump.

Another problem was “spirited driving” when the tank was only quarter full. Electric pumps don’t typically suck very well. You need to set them up such that gravity feeds the inlet. If you can do that, they will push the fuel up to the carb very, very well. However, if you ever get into a situation where the fuel does not gravity feed to the pump, you’re going to be in trouble. The way my tank was set up, the pickup had a hump in it which gravity would have to overcome to get fuel to the pump. As long as there was at least five gallons in the tank (on a level surface...), the pump was fed just fine. Remember that pulling “G’s” in the corner will position the fuel the same as if it were on an incline. One day I took a corner especially aggressive with less than enough fuel to compensate. All the fuel sloshed to one side and the pickup was dry. The pump inlet went dry and I was smoked. Off to the side of the road I went. Because there was not enough fuel to overcome the hump, no amount of pump activity was going to help. That was when I decided I was ready to go to an in-tank pump.

The in-tank setup is the way to go and I highly recommend it to anyone making the conversion to an electric pump. The pump is quieter and because it sits at the bottom of the tank, you pretty much have to drain the tank to uncover the pump inlet.

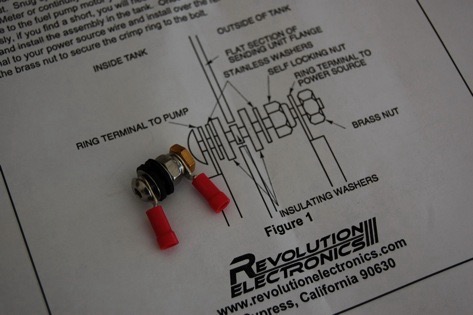

The only issue I ran into when converting to an in-tank setup was how to get the additional power line to the pump. You have to get battery voltage inside the tank without creating a leak. And you have to do this with a material which is unaffected by gasoline. Gasoline is some pretty nasty stuff, so this last requirement is actually harder than it sounds. My first attempt was with regular Buna-N O-rings and washers. Bad move. After just a few hours, they swell enough to start dripping fuel out of the tank. The “secret” is fluoroelastomers. This material is great. It is not cheap like Buna-N, but it tolerates gasoline like it is water.

This kit is enough parts to transfer one power line into the fuel tank. Stainless steel and brass hardware for the primary components with fluoroelastomer washers and a square-cross-section O-ring keep you from leaking fuel or shorting to the tank. Save yourself the hassle of finding all the parts. Complete instructions included. Works with flanges as thick as 0.100".

$9.99 PN 14007 (Contact us to purchase this item sales@revolutionelectronics.com)

California Residents - WARNING:Cancer and Reproductive Harm - www.P65Warnings.ca.gov